Abstract

The challenge of treating industrial dyes in wastewater is significant due to environmental regulations and the inefficiency of single treatment methods. This article introduces a modified design of a pilot-scale micro-pre-treatment unit that uses a solar-triggered advanced oxidation process reactor to control influent variability and mitigate textile effluents. The technique combines primary, secondary, and tertiary treatment steps with ZnO/ZnO-GO NanoMat-based advanced oxidation process, demonstrating complete remediation of industrial grade effluent. Additionally, machine learning models are proposed for predicting water quality parameters, with multi-linear regression and Artificial Neural network modeling providing accurate and robust predictions.

Introduction

Industrial nations face increased pollution from textile and steel industries, requiring scientific efforts to mitigate effluent discharge. Textile industries use significant water amounts, leading to contamination of natural resources with carcinogenic substances. The limited availability of water resources necessitates the development of technologies that promote reusability and sustainability. Existing conventional treatment methodologies have limitations, especially during complex secondary aeration processes. Advanced Oxidation Processes (AOPs) have emerged as a solution to remove complex chemicals and enable reuse for scaled applications.

Results

The pilot plant developed in this study has been commissioned at a medium-scale textile production unit in India. It evaluates the combination of primary, secondary, and tertiary treatment processes for textile/steel wastewater mixing. The plant effectively controls the influent variability and achieves significant reduction in wastewater parameters, making the discharge reusable.

Combination treatment processes components

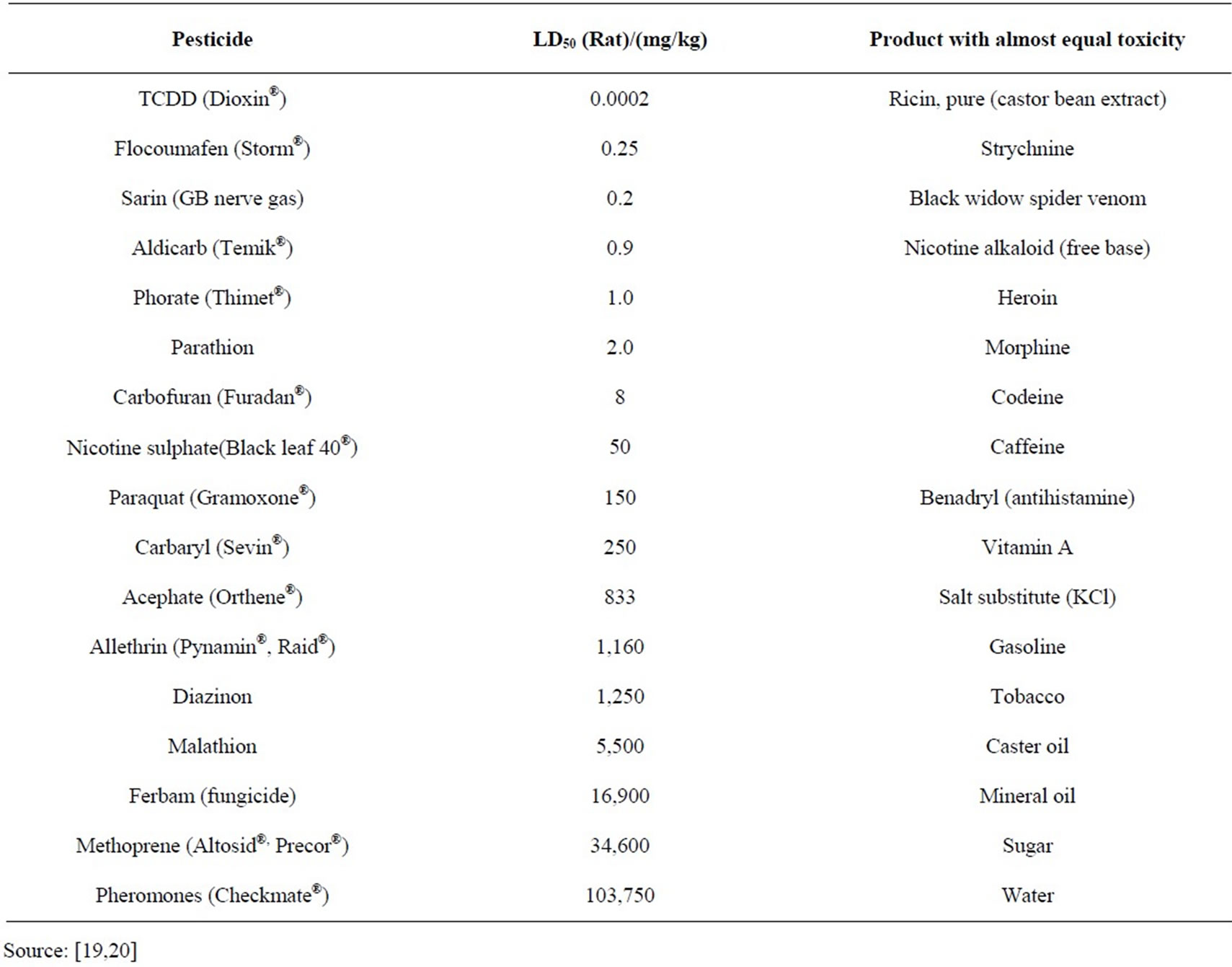

The treatment process includes coagulation and flocculation (C&F), activated sand-based filtration (SF), photocatalytic reactors with ZnO-type nanomaterial coated over metallic filter plates, and polyacrylonitrile (PAN) fiber and activated carbon filtration (ACF) steps.

Pre-filtration (coagulation & flocculation) unit

The C&F chamber removes colloidal suspensions by precipitation using floc creation mechanism.

Activated sand filtration (SF) unit

Acid-activated sand is used for dye sorption process, increasing surface area and pore volume for greater adsorption sites.

Fabrication of ZnO/ZnOGO coated SS sheets (NanoMat)

ZnO/ZnOGO nanocomposite is grown over a perforated stainless steel (SS304) sheet substrate to withstand corrosive conditions.

Photocatalytic nano-mat (NM) reactor

The reactor accommodates serially placed perforated ZnO/ZnOGO coated SS sheet panels for effective photocatalytic remediation.

Nano-filtration (NF) units

Treated dye wastewater is passed through PAN fiber filter and Activation Carbon filter (ACF) for performing the Nano-Filtration (NF) process step.

Structural characterization of photocatalytic nano-mat filter

ZnO and ZnOGO NanoMat are characterized using Field Emission Scanning Electron Microscopy (FESEM).

Pilot unit operational details

The pilot unit includes various treatment stages that reduce wastewater parameters significantly, resulting in a zero liquid discharge (ZLD) system.

Study of photocatalytic filter performance

Photocatalytic efficiency of the ZnO Nano-Mat is analyzed using UV-vis absorbance spectra, showing significant discolouration of industrial wastewater.

Wastewater parameters analysis

Wastewater parameters such as COD, BOD, TDS, TOC, turbidity, and pH are monitored after each treatment stage.

Data-driven predictive performance modeling

Data-driven modeling techniques are used to generate accurate prediction models using inlet parameters measured through online sensors.

Statistical analysis

A time series plot for outlet COD, TOC, and Turbidity removal efficiency is depicted for each process for 45 days of plant operation.

Process parameter identification using multi-linear regression

The outlet Process model identified using MLR determines efficient process parameters of the DWWTP.

Parameter estimation of the process response using artificial neural networks

ANN-based process predictive modeling captures data patterns for optimization of DWWTP operations.

Residual evaluation of the parametric prediction model

Residual analysis provides information about the model adequacy using the goodness-of-fit of the generated model.

Discussion

A unique method for treating textile industrial wastewater using ZnO/ZnOGO NanoMat combined with advanced oxidation processes is presented. The plant achieves significant reduction in wastewater parameters, making the discharge reusable. Predictive performance modeling using multi-linear regression and artificial neural networks provides accurate predictions for organic carbon removal.

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

Code availability

The code used to develop individual figures is available upon request to the corresponding author.

1. Which SDGs are addressed or connected to the issues highlighted in the article?

The Sustainable Development Goals (SDGs) addressed in the article are:

- SDG 6: Clean Water and Sanitation

- SDG 9: Industry, Innovation, and Infrastructure

- SDG 12: Responsible Consumption and Production

2. What specific targets under those SDGs can be identified based on the article’s content?

The specific targets under the SDGs based on the article’s content are:

- Target 6.3: Improve water quality by reducing pollution, eliminating dumping and minimizing release of hazardous chemicals and materials

- Target 6.4: Substantially increase water-use efficiency across all sectors and ensure sustainable withdrawals and supply of freshwater

- Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies

- Target 12.4: Achieve the environmentally sound management of chemicals and all wastes throughout their life cycle

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

The indicators mentioned or implied in the article that can be used to measure progress towards the identified targets are:

- Reduction in pollution levels caused by effluent discharge from textile industries

- Efficiency of water treatment processes in removing organic matter, suspended solids, dye-based inorganics, etc.

- Reuse of treated wastewater for different industrial purposes

- Compliance with Inland Water Discharge Standards (IWDS)

- Prediction models for estimating water quality parameters using machine learning models

4. Create a table with three columns titled ‘SDGs, Targets and Indicators” to present the findings from analyzing the article.

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 6: Clean Water and Sanitation | Target 6.3: Improve water quality by reducing pollution | Reduction in pollution levels from textile industries |

| Target 6.4: Increase water-use efficiency | Efficiency of water treatment processes | |

| SDG 9: Industry, Innovation, and Infrastructure | Target 9.4: Upgrade infrastructure for sustainability | Use of advanced oxidation process reactors in wastewater treatment |

| SDG 12: Responsible Consumption and Production | Target 12.4: Manage chemicals and wastes sustainably | Compliance with IWDS, reuse of treated wastewater |

| Prediction models for water quality parameters using ML models |

Copyright: Dive into this article, curated with care by SDG Investors Inc. Our advanced AI technology searches through vast amounts of data to spotlight how we are all moving forward with the Sustainable Development Goals. While we own the rights to this content, we invite you to share it to help spread knowledge and spark action on the SDGs.

Fuente: nature.com

Join us, as fellow seekers of change, on a transformative journey at https://sdgtalks.ai/welcome, where you can become a member and actively contribute to shaping a brighter future.