Report on Supply Chain Planning and Its Alignment with Sustainable Development Goals (SDGs)

Introduction

Over the past five years, supply chains have encountered unprecedented challenges driven by e-commerce demands, trade pressures, and increasingly complex supplier networks. These challenges have compelled executives to focus on optimizing supply chain operations amidst concerns such as tariffs and potential trade wars. Supply Chain Planning (SCP) has emerged as a critical operational function, essential for leveraging commercial and technical resources effectively.

Supply Chain Planning: Definition and Importance

Supply Chain Planning is a vital subset of Supply Chain Management (SCM) that begins with accurate forecasting of customer demand. It involves detailed planning of the journey of materials and products from raw material stages to final consumers. SCP forms the foundation for overall supply chain operations and supports day-to-day decision-making across multiple company functions.

Alignment with Sustainable Development Goals

- SDG 9 (Industry, Innovation, and Infrastructure): SCP fosters innovation in supply chain processes and infrastructure development.

- SDG 12 (Responsible Consumption and Production): Through demand forecasting and inventory management, SCP promotes efficient resource use and waste reduction.

- SDG 8 (Decent Work and Economic Growth): SCP supports economic growth by improving business efficiency and resilience.

Key Trends Accelerating the Importance of Supply Chain Planning

- Rise in Supply Chain Complexity

- Increasing complexity requires continuous efficiency improvements and responsiveness, enabling companies to realign assets and maximize value.

- SDG 9 is supported by these efforts to innovate and enhance industrial processes.

- Managing Multifunctional Business Processes

- Effective planning integrates multiple organizational functions, developing both technical and interpersonal skills among planners who often lead critical business processes.

- This supports SDG 8 by promoting inclusive and sustainable economic growth through skilled workforce development.

- Heightened Consumer Expectations for Customized Products and Services

- Retailers respond to consumer demand for customization, increasing SKU complexity and pressure on demand fulfillment systems. SCP enables product innovation, simplification, and SKU rationalization.

- These strategies contribute to SDG 12 by optimizing production and reducing waste.

Responsibility for Supply Chain Planning

Supply chain planning is typically a centralized function managed by supply chain planners who develop and execute strategies to meet business demands. These professionals utilize tools such as supply chain modeling, inventory management, and forecasting. The trend is moving from siloed planning to collaborative approaches enabled by cloud-based solutions, enhancing transparency and responsiveness.

SDG Implications

- SDG 9: Adoption of cloud technologies promotes innovation and infrastructure development.

- SDG 17 (Partnerships for the Goals): Collaborative planning fosters partnerships across functions and organizations.

Key Components of Supply Chain Planning

- Demand Forecasting

- Utilizes historical data, market trends, and customer insights to predict future demand, ensuring optimal inventory levels.

- Supports SDG 12 by minimizing overproduction and waste.

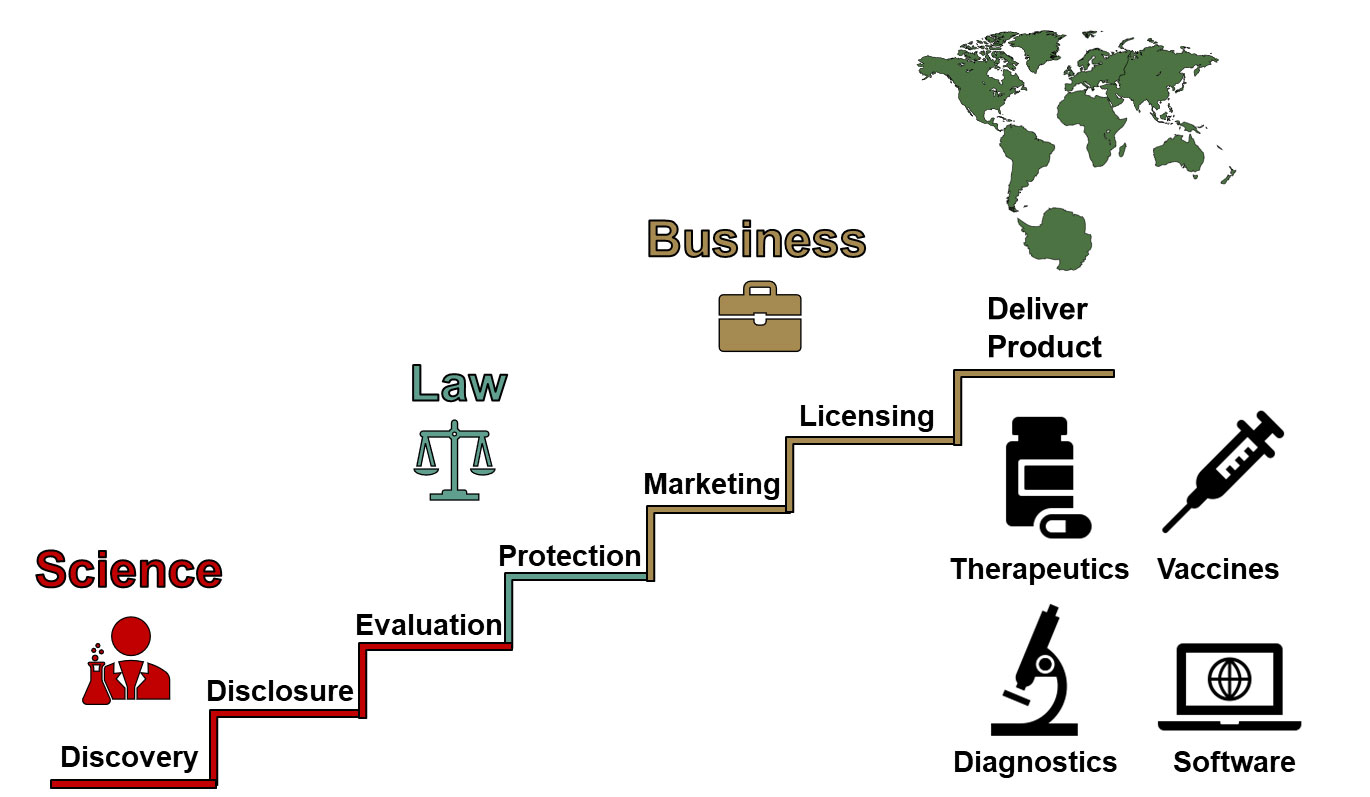

- Supply Chain Management

- Oversees conversion of raw materials into finished products, focusing on continuous improvement, increased velocity, and adoption of new technologies.

- Aligns with SDG 9 and SDG 8 through efficient industrial processes and economic growth.

- Risk Management

- Identifies potential disruptions such as natural disasters and supplier issues, developing contingency plans and “what-if” scenarios.

- Enhances resilience, contributing to SDG 13 (Climate Action) and SDG 11 (Sustainable Cities and Communities).

- Inventory Management

- Balances supply and demand to meet customer needs without excessive carrying costs.

- Promotes responsible resource use in line with SDG 12.

- Sales & Operations Planning (S&OP)

- Integrates data on customer demand, production, inventory, and marketing to inform supply chain decisions, requiring improved data quality and alignment of company goals.

- Supports SDG 8 by enhancing organizational efficiency and decision-making.

Conclusion and Future Outlook

The ARC Advisory Group will soon update its annual Supply Chain Planning Market Analysis, led by analyst Gaven Simon. Stakeholders interested in discussing developments in supply chain solutions or market trends are encouraged to contact the ARC supply chain team at gsimon@arcweb.com.

In summary, effective Supply Chain Planning is integral to achieving multiple Sustainable Development Goals by promoting innovation, responsible production, economic growth, resilience, and partnerships. Organizations that prioritize SCP contribute significantly to sustainable and inclusive global development.

1. Sustainable Development Goals (SDGs) Addressed or Connected to the Issues Highlighted in the Article

- SDG 8: Decent Work and Economic Growth

- The article discusses supply chain planning as a critical business function that supports economic activities, efficiency, and business growth.

- SDG 9: Industry, Innovation, and Infrastructure

- Focus on supply chain complexity, innovation in planning, and leveraging technology such as cloud solutions aligns with building resilient infrastructure and fostering innovation.

- SDG 12: Responsible Consumption and Production

- Inventory management, demand forecasting, and SKU rationalization contribute to sustainable consumption and production patterns by reducing waste and optimizing resource use.

- SDG 13: Climate Action

- Risk management related to natural disasters and disruptions implies a focus on resilience and adaptation to climate-related impacts.

2. Specific Targets Under Those SDGs Identified Based on the Article’s Content

- SDG 8: Decent Work and Economic Growth

- Target 8.2: Achieve higher levels of economic productivity through diversification, technological upgrading, and innovation.

- Target 8.3: Promote development-oriented policies that support productive activities and decent job creation.

- SDG 9: Industry, Innovation, and Infrastructure

- Target 9.1: Develop quality, reliable, sustainable, and resilient infrastructure to support economic development and human well-being.

- Target 9.5: Enhance scientific research, upgrade technological capabilities of industrial sectors.

- SDG 12: Responsible Consumption and Production

- Target 12.2: Achieve sustainable management and efficient use of natural resources.

- Target 12.5: Substantially reduce waste generation through prevention, reduction, recycling, and reuse.

- SDG 13: Climate Action

- Target 13.1: Strengthen resilience and adaptive capacity to climate-related hazards and natural disasters.

3. Indicators Mentioned or Implied in the Article to Measure Progress Towards the Identified Targets

- Supply Chain Efficiency and Responsiveness

- Indicators such as inventory turnover rates, order fulfillment times, and supply chain velocity can measure improvements in economic productivity and operational efficiency (related to SDG 8 and 9).

- Innovation and Technology Adoption

- Use of cloud-based planning solutions and supply chain modeling tools can be tracked as indicators of technological upgrading and innovation (related to SDG 9).

- Resource Use and Waste Reduction

- Metrics on SKU rationalization, inventory management effectiveness, and reduction in excess inventory indicate progress towards sustainable consumption and production (SDG 12).

- Risk Management and Resilience

- Indicators such as the number of contingency plans developed, frequency of supply chain disruptions, and recovery times measure resilience to climate-related and other risks (SDG 13).

4. Table: SDGs, Targets and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 8: Decent Work and Economic Growth |

|

|

| SDG 9: Industry, Innovation, and Infrastructure |

|

|

| SDG 12: Responsible Consumption and Production |

|

|

| SDG 13: Climate Action |

|

|

Source: logisticsviewpoints.com