Advancing Sustainable Development Goals through Electrodialysis Treatment of Hyper-Saline Brine

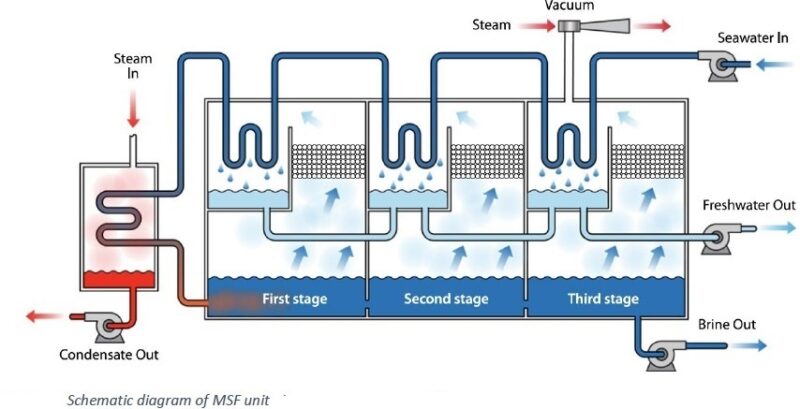

This report details an investigation into the application of electrodialysis (ED) technology for treating hyper-saline brines, a byproduct of Reverse Osmosis (RO) desalination. The study is structured around two primary scenarios, both of which directly contribute to several United Nations Sustainable Development Goals (SDGs), particularly SDG 6 (Clean Water and Sanitation), SDG 9 (Industry, Innovation, and Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 14 (Life Below Water).

Scenario 1: Resource Recovery from Brine for Sustainable Industrial Processes (SDG 9, SDG 12)

The first scenario focuses on transforming desalination waste into valuable industrial chemicals, embodying the principles of a circular economy and contributing to sustainable industrial practices.

Objective and Methodology

The primary objective was to produce Hydrochloric Acid (HCl) and Sodium Hydroxide (NaOH) from hyper-saline brines. This approach aligns with SDG 12 (Responsible Consumption and Production) by converting a waste stream into valuable feedstocks, reducing the need for virgin materials and minimizing industrial waste.

- Feed Source: Hyper-saline reject brine from RO processes with Total Dissolved Solids (TDS) ranging from 50 to 100 g/L.

- Key Variables Investigated:

- Feed brine concentration (50, 75, and 100 g/L)

- Applied voltage (12, 18, and 24 V)

- Process duration (up to 6 hours)

Results and Contribution to SDGs

The production of HCl and NaOH was significantly influenced by the operational parameters, demonstrating a viable pathway for resource recovery.

- Voltage Impact: Applied voltage was the most critical factor. At a 50 g/L brine concentration, increasing the voltage from 12 V to 24 V elevated HCl production from 0.39 M to 0.82 M and NaOH from 0.37 M to 0.78 M. This highlights an innovation in process control, supporting SDG 9 (Industry, Innovation, and Infrastructure).

- Concentration Impact: Doubling the initial brine salinity from 50 g/L to 100 g/L did not proportionally increase chemical output, indicating an optimal concentration range for efficiency.

- Process Optimization: A statistical model (two-factor interaction model) was developed with a high correlation coefficient (R² = 94.4% for HCl, R² = 98.09% for NaOH), confirming the model’s accuracy for predicting outcomes and optimizing the process.

- Optimal Conditions: The model identified optimal conditions at a feed concentration of 75 g/L and a voltage of 24 V, yielding experimental concentrations of 0.86 M HCl and 0.93 M NaOH. This aligns with typical RO brine concentrations (60-85 g/L), making the process highly practical for existing desalination infrastructure.

Scenario 2: Mitigating Marine Pollution and Protecting Aquatic Ecosystems (SDG 6, SDG 14)

The second scenario addresses the direct environmental impact of brine disposal, aiming to protect marine ecosystems and ensure the sustainability of desalination as a source of clean water.

Objective and Methodology

The goal was to reduce the TDS of brine from a typical 75 g/L to a target range of 30-40 g/L, which is comparable to natural seawater salinity. This directly supports SDG 14 (Life Below Water) by preventing marine pollution from high-salinity discharge and SDG 6 (Clean Water and Sanitation) by ensuring that water production does not degrade aquatic environments.

- Feed Source: Constant brine feed concentration of 75 g/L.

- Key Variables Investigated:

- Applied voltage (12, 18, and 24 V)

- Process duration (up to 6 hours)

- Modeling: A quadratic model was employed, demonstrating an excellent fit with the experimental data (R² = 99.04%).

Results and Contribution to SDGs

The experiments confirmed that ED is highly effective at reducing brine salinity to environmentally acceptable levels.

- TDS Reduction: A synergistic effect between voltage and time was observed. At 24 V, the salinity was reduced by 81.3% after 6 hours.

- Optimal Conditions for Discharge: The model predicted that a TDS of 35 g/L could be achieved at 24 V after 143 minutes, with experimental results confirming a final TDS of approximately 30 g/L. This achieves the goal of producing an effluent safe for marine disposal, a critical step for SDG 14.1.

- Simultaneous Resource Recovery: While reducing TDS, the process still produced valuable chemicals (e.g., 0.86 M HCl and 0.92 M NaOH at 24 V after 6 hours), reinforcing the circular economy benefits outlined in SDG 12.

Energy Consumption and Scale-Up Implications

Energy Profile (SDG 7, SDG 13)

Energy consumption is a critical factor for the economic and environmental viability of the process. Understanding energy use is essential for contributing to SDG 7 (Affordable and Clean Energy) and SDG 13 (Climate Action) by minimizing the carbon footprint of water treatment.

- Energy consumption increased with higher applied voltage, which corresponds to higher rates of chemical production and TDS removal.

- At the optimal feed concentration of 75 g/L, the specific energy consumption (SEC) was recorded, providing crucial data for balancing operational costs with environmental benefits.

- The reported energy consumption values were significantly lower than those in comparable studies, indicating a highly efficient process.

Scale-Up and Future Outlook

The combination of lab-scale experimentation with robust statistical modeling provides a strong foundation for scaling this technology. This innovative approach reduces the costs and efforts associated with pilot-scale testing, accelerating the adoption of sustainable brine management technologies in line with SDG 9. By treating high-concentration brines (up to 100 g/L), this study pushes the boundaries of current ED applications and offers a comprehensive solution that simultaneously addresses waste valorization and environmental protection.

Analysis of Sustainable Development Goals (SDGs) in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

-

SDG 6: Clean Water and Sanitation

The article focuses on treating brine, a high-salinity wastewater reject from Reverse Osmosis (RO) desalination processes. By developing a method to treat this brine, the research contributes to improving water quality and managing wastewater from desalination, a critical source of fresh water.

-

SDG 7: Affordable and Clean Energy

The study extensively analyzes the energy consumption of the electrodialysis (ED) process. It investigates how variables like voltage affect the Specific Energy Consumption (SEC) and seeks to find an optimal balance, which relates to improving energy efficiency in industrial processes.

-

SDG 9: Industry, Innovation, and Infrastructure

The research presents an innovative technological process (electrodialysis) to retrofit the desalination industry. It aims to make the industry more sustainable by increasing resource-use efficiency and adopting a cleaner, more environmentally sound process for managing waste brine.

-

SDG 12: Responsible Consumption and Production

The core of the article is about creating a circular economy model for desalination. It takes a waste product (hyper-saline brine) and recycles it to produce valuable chemicals (HCl and NaOH), thereby reducing waste generation and promoting the efficient use of resources.

-

SDG 14: Life Below Water

A primary goal of the research is to reduce the environmental impact of brine disposal. The second scenario explicitly aims to lower the brine’s Total Dissolved Solids (TDS) to a level (30-40 g/L) that matches the natural salinity of the sea, directly addressing the issue of marine pollution from land-based desalination plants.

2. What specific targets under those SDGs can be identified based on the article’s content?

-

Target 6.3: Improve water quality by reducing pollution and increasing wastewater treatment

The article directly addresses this target by proposing a method to treat industrial wastewater (brine reject from RO). The process reduces the pollution potential of the brine by lowering its salinity and recovering chemicals, turning a waste stream into a treated effluent with valuable by-products.

-

Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable and resource-efficient

The study provides a clear example of retrofitting the desalination industry with a cleaner technology (electrodialysis). The process improves resource-use efficiency by recovering HCl and NaOH from a waste stream, as stated: “the target of the current study was to produce HCl and NaOH since these chemicals are needed by the desalination facilities for pretreatment.”

-

Target 12.5: Substantially reduce waste generation through prevention, reduction, recycling and reuse

The entire premise of the article aligns with this target. It focuses on reducing the waste volume and impact of brine by recycling its components into useful chemicals. This is a direct application of recycling and reuse to minimize industrial waste.

-

Target 14.1: Prevent and significantly reduce marine pollution from land-based activities

The second scenario is explicitly designed to meet this target. The goal is to reduce the brine’s TDS from a high of 75 g/L to “the range of 30 and 40 g/L,” making it “suitable for disposal in direct in the sea.” This directly mitigates the harmful effects of high-salinity discharge on marine ecosystems.

-

Target 7.3: Double the global rate of improvement in energy efficiency

The article’s detailed analysis of “energy consumption and specific energy consumption (SEC)” for the ED process under various conditions (voltage, time, concentration) demonstrates a focus on optimizing the technology for better energy efficiency. The text notes the importance of finding “a balance between the desired TDS… and the cost of the electrodialysis process,” which is directly linked to its energy consumption.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

-

Concentration of Total Dissolved Solids (TDS) in g/L

This is a primary indicator used throughout the article to measure the effectiveness of the treatment process. It directly measures progress towards Target 14.1 (reducing marine pollution) and Target 6.3 (improving water quality). The article specifies initial TDS levels (50-100 g/L) and target levels (30-40 g/L).

-

Concentration of recovered chemicals (HCl and NaOH) in Molarity (M)

The molar concentration of the produced HCl and NaOH is a key performance indicator for the resource recovery aspect of the process. This directly measures the efficiency of recycling and reuse, linking to Target 12.5 and Target 9.4. For example, the article identifies optimal production of “0.85 M HCl and 0.88 M NaOH.”

-

Specific Energy Consumption (SEC) in kWh/m³

The article explicitly measures and reports the SEC to evaluate the process’s efficiency. This serves as a direct indicator for Target 7.3 (energy efficiency) and the resource-efficiency aspect of Target 9.4. Table 2 and Table 4 are dedicated to presenting these values under different operating conditions.

4. Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 6: Clean Water and Sanitation | Target 6.3: By 2030, improve water quality by reducing pollution… and substantially increasing recycling and safe reuse globally. | Reduction in Total Dissolved Solids (TDS) of brine wastewater (g/L). |

| SDG 7: Affordable and Clean Energy | Target 7.3: By 2030, double the global rate of improvement in energy efficiency. | Specific Energy Consumption (SEC) of the electrodialysis process (kWh/m³). |

| SDG 9: Industry, Innovation, and Infrastructure | Target 9.4: By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies. | Concentration of recovered HCl and NaOH (Molarity), demonstrating resource-use efficiency. |

| SDG 12: Responsible Consumption and Production | Target 12.5: By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse. | Concentration of valuable chemicals (HCl and NaOH) produced from a waste stream (Molarity). |

| SDG 14: Life Below Water | Target 14.1: By 2025, prevent and significantly reduce marine pollution of all kinds, in particular from land-based activities. | Final concentration of Total Dissolved Solids (TDS) in treated brine (g/L), aiming to match the salinity of the receiving sea (30-40 g/L). |

Source: enveurope.springeropen.com