Report on the Digital Transformation of High-End Equipment Manufacturing and its Alignment with Sustainable Development Goals

Executive Summary

The digital transformation of high-end equipment manufacturing enterprises is a critical enabler for advancing the manufacturing value chain and achieving high-quality, sustainable development. This report evaluates the digital transformation level of 124 such enterprises from 2016 to 2021, utilizing an evaluation index system based on the Input-Process-Output (I-P-O) theoretical model. This framework directly aligns with key Sustainable Development Goals (SDGs), particularly SDG 9 (Industry, Innovation, and Infrastructure), SDG 8 (Decent Work and Economic Growth), and SDG 12 (Responsible Consumption and Production). Using a VHSD-EM model for evaluation and a barrier model for analysis, the findings indicate a slow but positive trend in digital transformation. However, significant barriers remain, primarily concerning strategic awareness, resource allocation, and innovation efficiency, which impede the full realization of SDG targets. This report identifies these obstacles and provides recommendations to accelerate a sustainable industrial transition.

1. Introduction: Digital Transformation as a Driver for Sustainable Industrialization

The high-end equipment manufacturing industry is central to national economic strategy and the promotion of sustainable industrialization as outlined in SDG 9. The integration of digital technologies is the primary mechanism for achieving high-quality development, enhancing economic productivity (SDG 8), and fostering innovation. As enterprises increasingly adopt digital solutions, it becomes imperative to assess their progress and identify constraints. This report addresses the current state of digital transformation in China’s high-end equipment manufacturing sector, analyzing its effectiveness and the primary obstacles hindering progress. A comprehensive understanding of these dynamics provides crucial insights for aligning industrial practices with the 2030 Agenda for Sustainable Development.

While existing research offers a foundation for evaluation, it often lacks a process-oriented perspective and dynamic comparability. This study introduces an I-P-O model to analyze the transformation as a continuous process, encompassing awareness (input), implementation (process), and benefits (output). This approach provides a clearer view of the internal mechanisms driving transformation and their contribution to sustainable outcomes. By employing the VHSD-EM model, this report ensures a dynamic and objective assessment, offering valuable reference points for enterprises striving to enhance their contribution to the SDGs.

2. Analytical Framework and Methodology

2.1. The Digital Transformation Process and its Link to SDGs

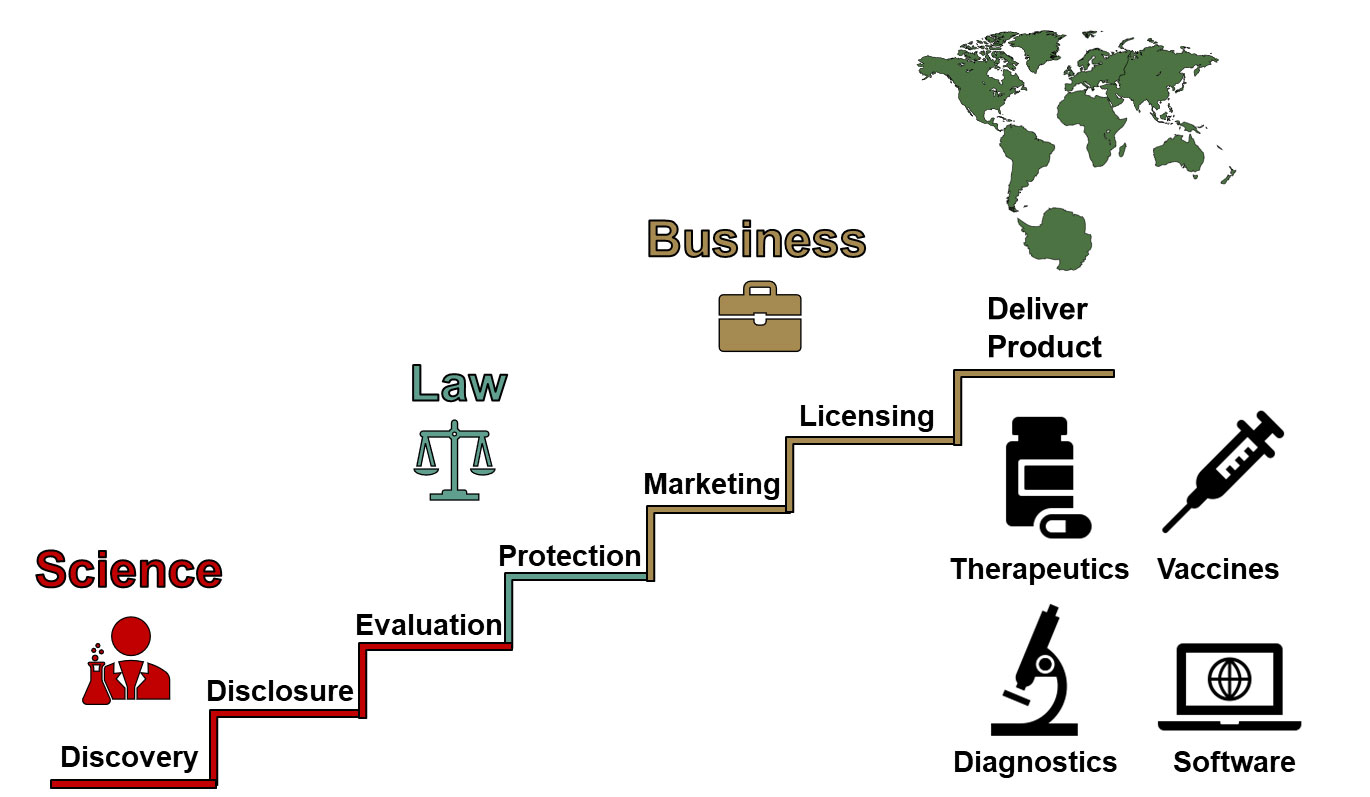

This report analyzes the digital transformation of high-end equipment manufacturing enterprises through a process-oriented framework based on the I-P-O model. This structure allows for a systematic evaluation of how enterprises translate strategic intent into sustainable outcomes.

- Input Stage (Digital Transformation Awareness): This stage involves the ideological shift towards digitalization, driven by technological, institutional, market, and industrial pressures. It reflects an enterprise’s strategic alignment with the goals of sustainable industrialization (SDG 9) and its readiness to innovate. Awareness is the catalyst for investing in cleaner, more efficient technologies and fostering a culture of continuous improvement.

- Process Stage (Digital Transformation Implementation): This stage focuses on the concrete actions taken by enterprises, including the investment in digital talent and capital. This directly corresponds to SDG 9’s call for upgrading infrastructure and retrofitting industries to make them sustainable. It also supports SDG 8 by investing in a skilled workforce capable of navigating the new industrial landscape.

- Output Stage (Digital Transformation Benefits): This stage measures the outcomes of transformation, primarily through enhanced operational and innovation efficiency. These benefits are direct contributors to SDG 12 (Responsible Consumption and Production) by enabling resource optimization and waste reduction. Furthermore, improved innovation efficiency drives progress towards SDG 9 by creating new technologies and business models for a sustainable future.

2.2. Construction of a Sustainable Development-Oriented Evaluation Index System

An evaluation index system was established across the three dimensions of the I-P-O model, with indicators selected for their relevance to both digital transformation and sustainable development.

- Digital Transformation Awareness (Input): This dimension assesses management’s recognition of the need for change, a prerequisite for aligning with sustainable goals.

- Digital Production and Management Transformation: Reflects commitment to modernizing processes for greater efficiency (SDG 9, SDG 12).

- Digital Business Model and Strategic Orientation: Measures the integration of sustainability and foresight into corporate strategy (SDG 9).

- Digital Transformation Reforms (Process): This dimension quantifies the investment in capabilities required for a sustainable transition.

- Digital Talent Investment: Measures investment in human capital, crucial for decent work and economic growth (SDG 8).

- Digital Capital Investment: Assesses investment in digital infrastructure and R&D, the backbone of industrial innovation (SDG 9).

- Digital Transformation Benefits (Output): This dimension evaluates the efficiency gains that signify progress towards sustainability.

- Operational Efficiency: Includes revenue, profit, and cost efficiencies, which are indicators of responsible resource management (SDG 12).

- Innovation Efficiency: Measured by digital patent output, reflecting the capacity to contribute to technological advancement and sustainable solutions (SDG 9).

2.3. Evaluation and Diagnostic Models

To ensure a robust and dynamic analysis, this report utilizes a combined modeling approach:

- VHSD-EM Model: This hybrid model was employed to assign objective weights to the evaluation indicators, capturing both cross-sectional differences and temporal dynamics. This method overcomes the limitations of static evaluations and provides a more credible assessment of progress over time.

- Impediment Model: Following the evaluation, an obstacle degree model was used to diagnose the primary factors hindering digital transformation. This allows for the identification of critical barriers that must be addressed to accelerate progress towards SDG 9 and related goals.

3. Evaluation of Digital Transformation Levels (2016-2021)

3.1. Overall Trends and Contribution to Sustainable Economic Growth

The overall digital transformation level of high-end equipment manufacturing enterprises demonstrated a gradual upward trend from 2016 to 2021. While this indicates progress, the slow growth rate suggests that the industry’s potential to drive innovation and sustainable development (SDG 9) is not yet fully realized. A slight decline in 2018, corresponding to trade-related disruptions, highlights the vulnerability of the transformation process to external shocks and underscores the need for resilient industrial policies.

Notably, state-controlled enterprises consistently ranked highest in transformation levels, suggesting that strong policy guidance and resource allocation can effectively steer industrial development towards national strategic priorities, including the SDGs. However, the gap between investment in transformation (process) and the resulting benefits (output) has widened, indicating inefficiencies that challenge the principles of responsible production (SDG 12). Many firms struggle to translate digital investments into tangible improvements in operational and innovation efficiency.

3.2. Sub-Field Evaluation and Uneven Progress on SDG 9

Analysis of five key sub-fields reveals significant disparities in digital transformation, indicating uneven progress toward the goals of SDG 9 across the sector.

- The satellite and application equipment industry leads in both transformation level and growth rate, showcasing a strong capacity for innovation.

- The rail transportation and intelligent manufacturing equipment industries show moderate but steady progress.

- The aviation and marine engineering equipment industries lag behind, though they have shown recent acceleration. These sectors face challenges in building integrated digital environments for design, manufacturing, and service, which are critical for enhancing their contribution to a sustainable industrial ecosystem.

This divergence highlights the need for targeted policies that address the unique challenges of each sub-field to ensure a more inclusive and comprehensive industrial transformation.

4. Impediment Factor Analysis: Barriers to Sustainable Industrial Transformation

4.1. Analysis of Impediments at the Indicator Level

The impediment model identified the top five factors consistently obstructing digital transformation, which directly hinder the achievement of sustainable development objectives.

- Structure of the Digital Executive Team: The most significant barrier, indicating that a lack of strategic leadership and digital literacy at the highest level prevents the integration of sustainability into corporate governance.

- Amount of Funds Raised for Digital Projects: A critical bottleneck that limits investment in the innovative technologies and resilient infrastructure required by SDG 9.

- Output Efficiency of Digital Invention Patents: Reflects a struggle to convert R&D investment into tangible innovations, slowing technological progress for sustainability.

- Internet Business Models: Difficulty in adapting business models to the digital era, limiting the potential for creating new, sustainable value chains.

- Digital Projects Under Construction: Challenges in the implementation phase of digital infrastructure projects.

The combined obstruction degree of these factors exceeded 55% and showed an upward trend, signaling a growing challenge to the industry’s sustainable transformation.

4.2. Analysis of Impediments at the Guideline Level

At a broader level, the primary barriers are concentrated in two dimensions:

- Digital Transformation Awareness (Input): Although awareness is improving, it remains a major obstacle. Enterprises have not fully internalized the strategic imperatives of digital and sustainable transformation, leading to hesitant or misguided efforts.

- Digital Transformation Implementation (Process): Despite increasing investment, the implementation phase is fraught with challenges. This points to a systemic issue where resources are not being deployed effectively to achieve desired sustainable outcomes.

Conversely, the impediment related to Digital Transformation Benefits (Output) is rising. This is a critical concern, as it suggests that even when enterprises invest in transformation, they are failing to realize the efficiency and innovation gains that underpin progress on SDG 9 and SDG 12. The diminishing marginal efficiency of R&D investment highlights a need for smarter, more strategic approaches to innovation.

5. Conclusion and Policy Implications for Advancing SDGs

5.1. Conclusion

This report provides a comprehensive evaluation of the digital transformation in China’s high-end equipment manufacturing industry from a process-oriented perspective aligned with the Sustainable Development Goals.

- The transformation process, structured by the I-P-O model, reveals a complex interplay between awareness, implementation, and benefits that directly impacts progress on SDG 8, SDG 9, and SDG 12.

- While a positive trend in digital transformation exists, the slow pace and significant disparities across sub-fields indicate that the industry’s full potential as an engine for sustainable development remains untapped.

- Key impediments are concentrated in strategic leadership, financial investment, and innovation efficiency. Addressing these barriers is crucial for accelerating the transition towards a more innovative, resilient, and sustainable industrial sector.

5.2. Policy Recommendations

To accelerate the digital and sustainable transformation of high-end equipment manufacturing enterprises, the following policy recommendations are proposed:

- Strengthen Leadership for Sustainable Transformation: The most critical barrier is the lack of strategic awareness at the executive level. Enterprises must prioritize optimizing their digital executive teams by recruiting leaders with proven experience in digital innovation. Collaborative formulation of digital strategies that explicitly integrate sustainability goals (SDG 9, SDG 12) is essential to foster a shared vision and drive meaningful change.

- Establish Robust Governance and Incentive Mechanisms: To overcome implementation barriers, enterprises should establish dedicated digital strategy committees to oversee planning and investment. This governance structure ensures that transformation is aligned with long-term sustainability objectives. Furthermore, incentive mechanisms, such as performance assessments tied to digital and sustainable outcomes, can enhance employee literacy and stimulate innovation, contributing to both SDG 8 and SDG 9.

- Accelerate Investment in Resilient Digital Infrastructure: Digital infrastructure is the foundation for sustainable industrialization. Increased financial investment is needed to build integrated platforms leveraging 5G, big data, AI, and the Industrial Internet of Things (IIoT). This directly supports SDG 9 (Target 9.1 and 9.4) by upgrading infrastructure and promoting the adoption of clean and environmentally sound technologies and industrial processes. Building digital twin workshops, data-sharing platforms, and intelligent production lines will provide the basic guarantee for a successful and sustainable transformation.

Analysis of Sustainable Development Goals (SDGs) in the Article

1. Which SDGs are addressed or connected to the issues highlighted in the article?

The article on the digital transformation of high-end equipment manufacturing enterprises connects to several Sustainable Development Goals (SDGs) by focusing on industrial innovation, economic growth, and the development of resilient infrastructure.

-

SDG 9: Industry, Innovation, and Infrastructure

This is the most prominent SDG in the article. The entire study revolves around upgrading the “high-end equipment manufacturing industry” through “digital transformation,” which is a core theme of SDG 9. The article discusses building resilient infrastructure by investing in digital technologies, fostering innovation through increased R&D and the development of “digital invention patents,” and promoting sustainable industrialization by enhancing efficiency and modernizing production processes.

-

SDG 8: Decent Work and Economic Growth

The article connects to SDG 8 by examining how digital transformation acts as a “critical driver for upgrading the manufacturing value chain and achieving high-quality development.” This focus on improving productivity, “operational efficiency,” and “profit efficiency” directly contributes to sustainable economic growth. The emphasis on a “knowledge-intensive” industry and the need for “digital technology talent” also relates to promoting productive employment.

-

SDG 12: Responsible Consumption and Production

Although not a central theme, SDG 12 is relevant. The article’s discussion of improving “operational efficiency” and “cost efficiency” through digital transformation implies more sustainable production patterns. By optimizing processes and value chains, enterprises can achieve “resource optimization” and “cost reduction,” which are essential for the efficient use of resources as outlined in SDG 12.

-

SDG 17: Partnerships for the Goals

The article implicitly addresses SDG 17 by highlighting the ecosystem that influences digital transformation. It notes the role of “policy initiatives,” “financial subsidies, tax incentives, and credit support” from the government, as well as “competitive pressure” and learning from “peer companies.” This illustrates the multi-stakeholder partnerships between the public sector (government) and the private sector (enterprises) needed to drive technological advancement and achieve sustainable development.

2. What specific targets under those SDGs can be identified based on the article’s content?

Several specific SDG targets can be identified from the article’s focus on technology, industry, and economic performance.

-

Targets under SDG 9 (Industry, Innovation, and Infrastructure)

- Target 9.2: Promote inclusive and sustainable industrialization. The article’s entire focus is on the advancement and evaluation of the “high-end equipment manufacturing industry,” a key component of modern industrialization.

- Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency. The article describes how digital transformation improves “operational efficiency” and enables “resource optimization,” which aligns with retrofitting industries for sustainability.

- Target 9.5: Enhance scientific research and upgrade the technological capabilities of industrial sectors. This target is directly addressed through the article’s analysis of “R&D personnel,” “digital capital investment,” and the “output efficiency of digital invention patents” as core components of digital transformation.

- Target 9.b: Support domestic technology development, research, and innovation. The article mentions how “policy initiatives” and government support encourage enterprises to pursue “independent research and development of core technologies.”

- Target 9.c: Significantly increase access to information and communications technology (ICT). The adoption of “big data, the Internet of Things (IoT), and artificial intelligence (AI)” and the development of “Internet-based business models” are central to the article, reflecting the application and importance of ICT.

-

Targets under SDG 8 (Decent Work and Economic Growth)

- Target 8.2: Achieve higher levels of economic productivity through diversification, technological upgrading, and innovation. The article frames “digital transformation” as the primary means for “technological upgrading” to achieve “high-quality development” and enhance “operational and innovation efficiency.”

-

Targets under SDG 12 (Responsible Consumption and Production)

- Target 12.2: Achieve the sustainable management and efficient use of natural resources. The drive for “operational efficiency,” “cost reduction,” and “resource optimization” through digital technologies directly contributes to this target by minimizing waste and improving resource productivity in manufacturing.

-

Targets under SDG 17 (Partnerships for the Goals)

- Target 17.17: Encourage and promote effective public, public-private, and civil society partnerships. The article acknowledges that digital transformation is driven by an ecosystem that includes “government policy support,” “financial subsidies,” and industry-wide “peer effects,” highlighting the importance of such partnerships.

3. Are there any indicators mentioned or implied in the article that can be used to measure progress towards the identified targets?

Yes, the article constructs an “evaluation index system” that contains several direct and implied indicators for measuring progress toward the identified targets.

-

Indicators for SDG 9

- For Target 9.5: The article explicitly uses indicators to measure R&D and innovation, such as the “proportion of R&D personnel,” the “proportion of R&D personnel salaries,” the “amount of funds raised for digital projects,” and the “output efficiency of digital invention patents.” These are direct measures of research and innovation capacity.

- For Target 9.4: The indicators of “operational efficiency” and “cost efficiency” serve as proxies for measuring improvements in resource-use efficiency within industries.

- For Target 9.c: The use of indicators like “application of foundational digital technologies” (AI, big data, IoT) and the adoption of “Internet-based business models” implies the level of ICT integration and access.

-

Indicators for SDG 8

- For Target 8.2: The article’s benefit-related indicators, such as “revenue efficiency,” “profit efficiency,” and overall “operational efficiency,” are direct measures of economic productivity at the firm level.

-

Indicators for SDG 12

- For Target 12.2: While not measuring natural resource use directly, the indicators of “operational efficiency” and “cost efficiency” are implied measures. Improved efficiency suggests that fewer resources are consumed per unit of economic output.

-

Indicators for SDG 17

- For Target 17.17: The article implies indicators by referencing drivers of transformation, such as government “financial subsidies, tax incentives, and credit support” and private sector investment through “funds raised for digital projects.” These can be quantified to measure the scale of public-private financial partnerships.

4. Summary Table of SDGs, Targets, and Indicators

| SDGs | Targets | Indicators Identified in the Article |

|---|---|---|

| SDG 9: Industry, Innovation, and Infrastructure |

9.2: Promote sustainable industrialization. 9.4: Upgrade industries for sustainability and resource-use efficiency. 9.5: Enhance scientific research and upgrade technological capabilities. 9.b: Support domestic technology development and innovation. 9.c: Increase access to ICT. |

– Level of digital transformation in the high-end equipment manufacturing industry (Implied for 9.2). – Operational efficiency and cost efficiency (Implied for 9.4). – Proportion of R&D personnel and their salaries (Directly for 9.5). – Amount of funds raised for digital projects (Directly for 9.5). – Output efficiency of digital invention patents (Directly for 9.5). – Government policy support and subsidies (Implied for 9.b). – Adoption of Internet-based business models and digital technologies (AI, IoT, big data) (Implied for 9.c). |

| SDG 8: Decent Work and Economic Growth | 8.2: Achieve higher economic productivity through technological upgrading and innovation. |

– Operational efficiency. – Revenue efficiency. – Profit efficiency. – Innovation efficiency. |

| SDG 12: Responsible Consumption and Production | 12.2: Achieve sustainable management and efficient use of natural resources. |

– Operational efficiency (Implied). – Cost efficiency and cost reduction (Implied). – Resource optimization through digital processes (Implied). |

| SDG 17: Partnerships for the Goals | 17.17: Encourage effective public-private partnerships. |

– Government financial subsidies, tax incentives, and credit support (Implied). – Private sector investment (funds raised for digital projects) in response to policy (Implied). |

Source: nature.com

![]()