LG Energy Solution’s Strategic Pivot Towards Energy Storage and its Alignment with Sustainable Development Goals

Q2 Performance and Strategic Realignment

A recent financial report from LG Energy Solution (LG ES) indicates a strategic pivot in response to evolving market conditions. While the company reported stable sales in the electric vehicle (EV) sector, quarterly revenue was adversely affected by constrained consumer purchasing and the reflection of declining metal prices in the average selling price (ASP). A significant portion of the reported profit (US$491 million) was attributed to production incentives in North America.

Advancing SDG 7: Affordable and Clean Energy

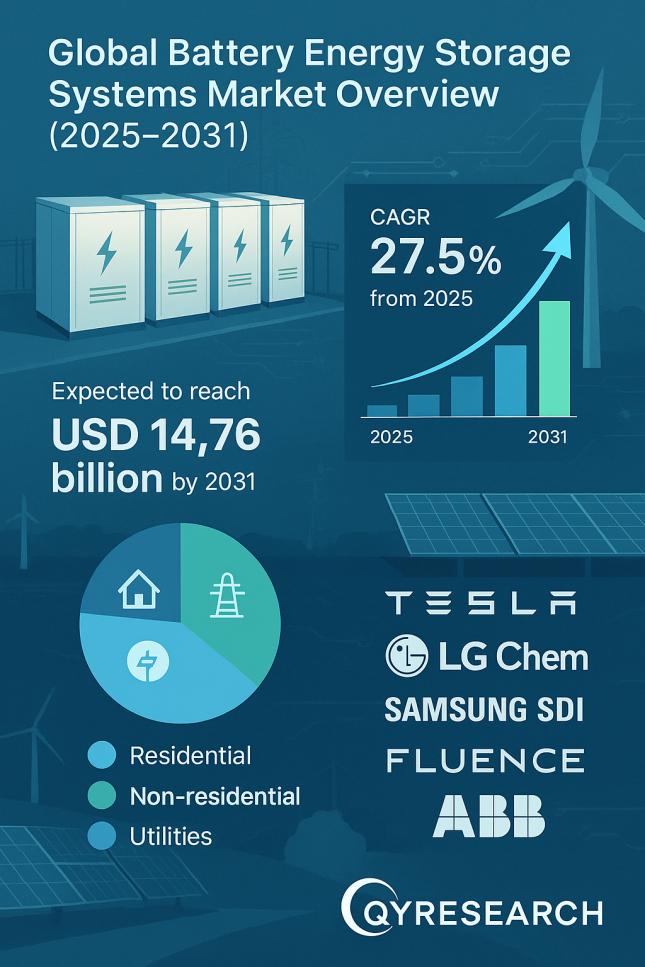

LG ES is making substantial contributions to Sustainable Development Goal 7 by enhancing its focus on Energy Storage Systems (ESS), which are critical for the widespread adoption of renewable energy.

- New ESS Production: The company commenced production at its new ESS battery facility in North America, a key achievement for the quarter. This facility directly supports the infrastructure needed for a clean energy transition.

- Meeting Rising Demand: LG ES anticipates continued growth in demand for energy storage, driven by the increasing integration of renewable energy sources and the power requirements of new AI data centers. This aligns with SDG 7’s target to increase the share of renewable energy in the global energy mix.

Fostering SDG 9: Industry, Innovation, and Infrastructure

The company’s investment and manufacturing strategies underscore a commitment to SDG 9 by building resilient infrastructure and fostering innovation.

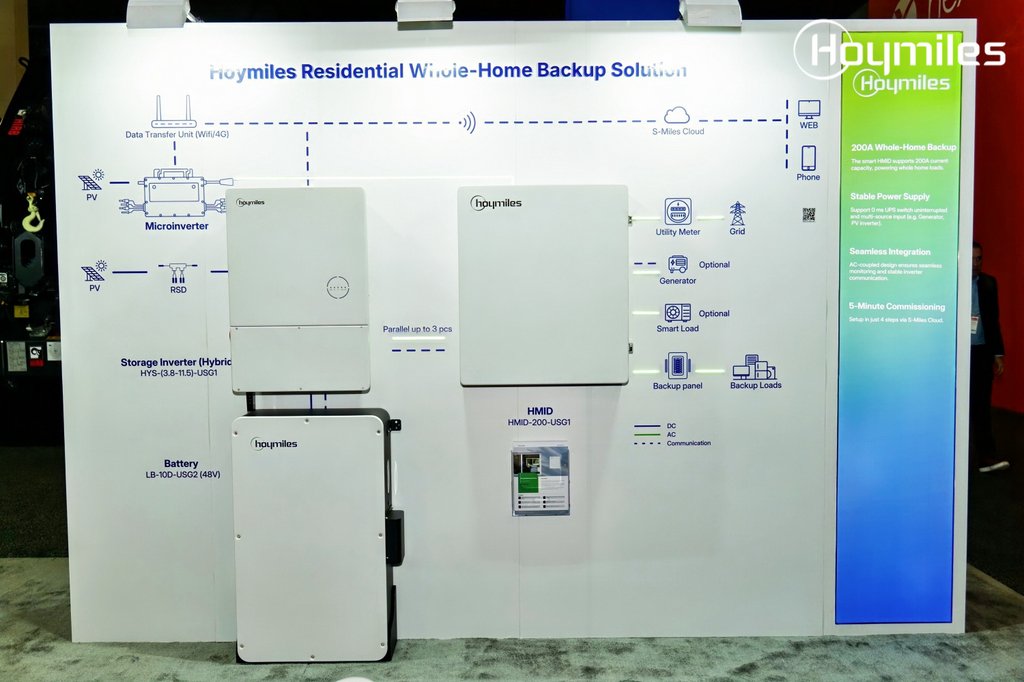

- Infrastructure Investment: A US$1.4 billion investment was made to retool EV cell lines at its Holland, Michigan complex into four new ESS cell production lines. This repurposing of existing infrastructure represents an efficient and innovative industrial strategy, avoiding the higher costs and longer timelines associated with greenfield projects.

- Securing Future Capacity: The full output capacity of the repurposed Michigan lines is reportedly booked for the next three to five years, signaling strong market confidence and securing a stable supply chain for large-scale clean energy projects.

- Technological Innovation: In the EV sector, investment is being channeled into R&D to develop next-generation batteries, including models capable of charging in under ten minutes and high-density lithium manganese-rich (LMR) batteries.

Supporting SDG 13: Climate Action through Market Adaptation

LG ES’s strategic decisions reflect an adaptation to global policies aimed at combating climate change, directly supporting SDG 13.

- Market Positioning: The company noted that new US restrictions on Foreign Entity of Concern (FEOC) Chinese equipment for projects seeking Investment Tax Credit (ITC) incentives could create a market advantage for non-Chinese manufacturers, potentially accelerating the build-out of secure, clean energy supply chains.

- Shift from EV to ESS: The rebalancing of production capacity from EV to ESS demonstrates a direct response to the growing urgency of grid-scale storage needed to support a decarbonized power sector.

Navigating Challenges with a Focus on SDG 8 and SDG 12

In response to market uncertainties, including a slowdown in EV market growth and the phaseout of certain subsidies, LG ES is adjusting its strategy to ensure sustainable economic growth (SDG 8) and responsible production (SDG 12).

- Responsible Investment: The company announced plans to adjust, scale down, and postpone existing investment plans to enhance cost efficiency and resource allocation. This includes curtailing investment in new production lines and continuing to reallocate resources.

- Market Context: This cautious approach is contextualized by wider market trends, where nearly 21GWh of planned US stationary storage battery cell manufacturing capacity has been cancelled and 19.2GWh has been postponed by various industry players since the start of the year.

SDGs Addressed in the Article

-

SDG 7: Affordable and Clean Energy

- The article focuses on the production of batteries for energy storage systems (ESS) and electric vehicles (EVs). ESS is crucial for grid stability and enabling higher adoption of renewable energy sources, as the article states, “…demand for energy storage to continue to increase, with rising renewable energy adoption… as the main drivers.” This directly supports the transition to cleaner energy.

-

SDG 9: Industry, Innovation, and Infrastructure

- The text is centered on industrial manufacturing, specifically the construction and retooling of battery production facilities (“gigafactory complex in Arizona,” “four new ESS cell production lines” in Michigan). It highlights significant investment in infrastructure (“investing US$1.4 billion”) and technological innovation, such as R&D efforts to “develop EV batteries that can be charged in under ten minutes” and batteries with “30% higher energy density.”

-

SDG 13: Climate Action

- The technologies discussed—EV batteries and energy storage—are fundamental tools for climate action. EVs reduce emissions from transportation, and ESS supports the integration of intermittent renewable energy, thereby decarbonizing the power sector. Government policies mentioned, like the “investment tax credit (ITC) incentives” and “consumer EV subsidy,” are direct climate change measures designed to accelerate the adoption of these technologies.

-

SDG 8: Decent Work and Economic Growth

- The article discusses large-scale economic activities, including a “US$10.8 billion IPO,” quarterly profits, and substantial investments in manufacturing. The establishment and operation of production facilities, such as the “new ESS battery facility in North America,” contribute to economic growth and job creation in the industrial sector.

-

SDG 12: Responsible Consumption and Production

- The article mentions LG ES’s decision to “retool EV cell lines at its existing production complex in Holland, Michigan, rather than proceed with an all-new gigafactory complex.” This act of repurposing existing industrial infrastructure instead of building a “greenfield facility” represents a more resource-efficient and sustainable production pattern.

Specific SDG Targets Identified

-

Target 7.2: Increase substantially the share of renewable energy in the global energy mix.

- The article connects the demand for energy storage directly to “rising renewable energy adoption.” Battery energy storage systems (BESS) are essential for storing energy from intermittent sources like solar and wind, thus enabling a greater share of renewables in the energy grid.

-

Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable… and with greater adoption of clean and environmentally sound technologies.

- LG ES’s strategy to “retool EV cell lines at its existing production complex” is a direct example of retrofitting an industry for a new, clean technology purpose (ESS batteries). This avoids the environmental impact and resource use of building a new “greenfield facility.”

-

Target 9.5: Enhance scientific research, upgrade the technological capabilities of industrial sectors… and encouraging innovation.

- The article explicitly states that for the rest of 2025, LG ES’s “investment activities in the EV space are more R&D-focused.” Specific innovation goals are mentioned, including developing “EV batteries that can be charged in under ten minutes” and “lithium manganese-rich (LMR) batteries with 30% higher energy density.”

-

Target 7.a: Promote investment in energy infrastructure and clean energy technology.

- The article details a “US$1.4 billion” investment into “four new ESS cell production lines.” This is a direct investment in clean energy technology infrastructure, aimed at increasing the production capacity for batteries that support both EVs and renewable energy grids.

Indicators for Measuring Progress

-

Indicator: Manufacturing capacity for energy storage batteries (in GWh).

- The article provides specific figures that can be used as indicators of industrial capacity for clean energy technology. It notes that “nearly 21GWh of new stationary storage battery cell manufacturing capacity… has been cancelled” and “close to the same amount (19.2GWh) has been postponed.” These figures directly measure the planned and actual growth of the ESS manufacturing sector.

-

Indicator: Financial investment in clean energy infrastructure.

- The article quantifies investment, stating LG ES is “investing US$1.4 billion into the four new ESS cell production lines.” This dollar amount is a direct indicator of financial flows towards building the infrastructure required for the clean energy transition.

-

Indicator: Performance metrics of new battery technology.

- Progress towards innovation targets can be measured by the specific performance goals mentioned. The article cites goals to develop batteries that can be “charged in under ten minutes” and achieve “30% higher energy density.” These are measurable indicators of technological advancement in the sector.

-

Indicator: Value and existence of government financial incentives.

- The article mentions policies such as the “investment tax credit (ITC) incentives” and the “consumer EV subsidy.” The status, value, and uptake of these incentives are clear indicators of government policy support for climate action and clean energy adoption.

SDGs, Targets, and Indicators Summary

| SDGs | Targets | Indicators |

|---|---|---|

| SDG 7: Affordable and Clean Energy | 7.2: Increase substantially the share of renewable energy in the global energy mix.

7.a: Promote investment in energy infrastructure and clean energy technology. |

– Demand for energy storage driven by “rising renewable energy adoption.” – Financial investment in production facilities (e.g., “US$1.4 billion into… ESS cell production lines”). |

| SDG 9: Industry, Innovation, and Infrastructure | 9.4: Upgrade infrastructure and retrofit industries to make them sustainable.

9.5: Enhance scientific research, upgrade the technological capabilities of industrial sectors. |

– Retooling of existing facilities (“retool EV cell lines at its existing production complex”). – R&D goals for battery performance (charge time “under ten minutes,” “30% higher energy density”). |

| SDG 13: Climate Action | 13.2: Integrate climate change measures into national policies, strategies and planning. | – Existence of government policies like “investment tax credit (ITC) incentives” and “consumer EV subsidy.” |

| SDG 8: Decent Work and Economic Growth | 8.2: Achieve higher levels of economic productivity through diversification, technological upgrading and innovation. | – Company financial performance (IPO value, quarterly profits). – Investment in new production lines and R&D. |

| SDG 12: Responsible Consumption and Production | 12.2: Achieve the sustainable management and efficient use of natural resources. | – Decision to repurpose an existing factory instead of building a new “greenfield facility.” – Manufacturing capacity of ESS batteries (e.g., “21GWh… cancelled,” “19.2GWh… postponed”). |

Source: energy-storage.news