Report on a Novel Recycling Strategy for Electric Vehicle Batteries in Alignment with Sustainable Development Goals

1.0 Introduction: Addressing an Emerging Environmental Challenge

The proliferation of electric vehicles (EVs) presents a significant challenge to sustainable waste management, particularly concerning expired lithium-ion batteries. A notable innovation from the University of Wisconsin-Milwaukee (UWM) directly addresses this issue, proposing a method to convert retired Lithium Iron Phosphate (LFP) batteries into agricultural fertilizer. This initiative provides a powerful example of a circular economy, contributing significantly to several United Nations Sustainable Development Goals (SDGs).

2.0 The Problem: End-of-Life EV Batteries and Sustainable Production

The transition to clean energy, a key component of SDG 7 (Affordable and Clean Energy) and SDG 13 (Climate Action), is creating a new waste stream. The primary challenges associated with retired LFP batteries include:

- High Disposal Costs: Traditional disposal methods are expensive and require specialized handling, posing an economic barrier to responsible waste management.

- Low Recycling Value: The economic incentive to recycle LFP batteries is minimal, as the value of recovered materials, beyond lithium, is low.

- Environmental Risk: Without a viable recycling pathway, millions of batteries risk becoming hazardous waste, undermining the principles of SDG 12 (Responsible Consumption and Production).

3.0 The Innovation: A Circular Solution for Industrial Waste

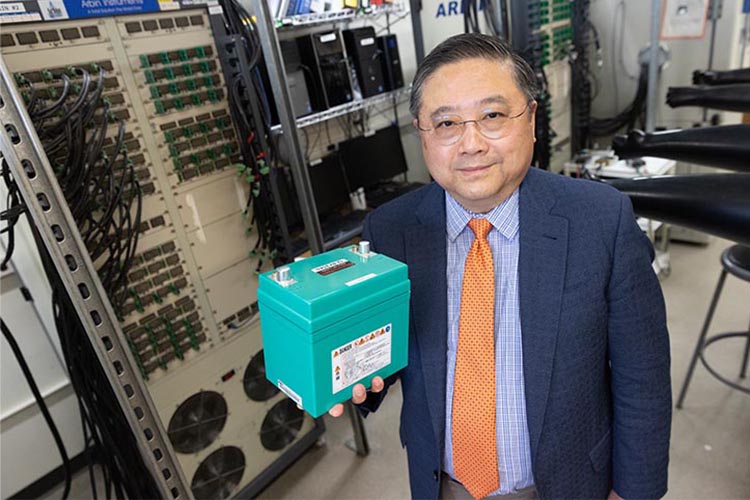

A research team led by Professor Deyang Qu has developed a process that transforms this environmental liability into a valuable resource, directly supporting SDG 9 (Industry, Innovation, and Infrastructure).

- Ion-Exchange Process: The method uses an ion-exchange process to recover lithium from the LFP battery materials.

- Nutrient Recovery: The remaining core elements—phosphorus, potassium, and nitrogen—are repurposed as key ingredients for agricultural fertilizer.

- Economic Viability: By creating a high-value product (fertilizer), the process establishes an economically sustainable model for battery recycling, turning a cost center into a revenue opportunity.

4.0 Alignment with Key Sustainable Development Goals

This project demonstrates a multi-faceted approach to sustainability, with direct contributions to the following SDGs:

- SDG 2 (Zero Hunger): By creating a domestic source of fertilizer, the initiative supports sustainable agriculture, enhances crop yields, and contributes to long-term food security.

- SDG 8 (Decent Work and Economic Growth): The project is poised to create high-tech jobs in green technology, foster workforce training, and stimulate local economic growth within Wisconsin’s manufacturing and agricultural sectors.

- SDG 12 (Responsible Consumption and Production): The core of the project is the establishment of a circular economy model. It fundamentally shifts the “take-make-dispose” pattern by upcycling industrial waste into a new, valuable product, thereby reducing waste and the need for virgin material extraction.

- SDG 15 (Life on Land): Creating fertilizer from recycled materials reduces the environmental impact associated with mining and transporting raw minerals, helping to protect terrestrial ecosystems.

5.0 Project Status and Future Directives

The concept has been successfully demonstrated with support from a UWM Discovery and Innovation Grant and in partnership with the USDA’s Agricultural Research Service.

Next Steps:

- Scale-Up Production: The immediate goal is to manufacture the fertilizer on a larger scale.

- Conduct Field Trials: A one-acre tomato crop trial is planned in collaboration with the USDA to compare the recycled fertilizer’s efficacy against conventional products.

- Commercialization: Positive trial results will be used to market the technology to major fertilizer companies, facilitating its integration into the broader agricultural supply chain.

This initiative positions Wisconsin to become a leader in self-sustaining battery recycling, leveraging its industrial and agricultural strengths to build a resilient and sustainable economic model.

Analysis of Sustainable Development Goals in the Article

-

SDGs Addressed or Connected

The article highlights issues and solutions that are directly connected to several Sustainable Development Goals (SDGs). The primary focus on recycling waste, creating economic value from it, and supporting agriculture links the project to goals concerning responsible consumption, economic growth, innovation, and food security.

-

SDG 2: Zero Hunger

The project’s outcome is the creation of fertilizer, a product described as “essential for increasing crop yields and maintaining food security.” By developing a domestic source of fertilizer from recycled batteries, the initiative directly supports sustainable agriculture and food production.

-

SDG 8: Decent Work and Economic Growth

The article frames the recycling strategy as a way to “transform a looming EV waste crisis into an environmental and economic opportunity.” It explicitly mentions that the project promises to “create high-tech jobs and provide workforce training,” contributing to sustainable economic growth and productive employment.

-

SDG 9: Industry, Innovation, and Infrastructure

The core of the article is a scientific innovation developed by Professor Deyang Qu and his team. This initiative represents an effort to “upgrade the technological capabilities of industrial sectors” by creating a new, environmentally sound industrial process for recycling. It also aims to build a resilient domestic supply chain for fertilizer ingredients, reducing “reliance on foreign imports.”

-

SDG 11: Sustainable Cities and Communities

The problem originates from batteries used in “EVs, E-delivery vans and E-buses,” which are key components of sustainable urban transportation. The article addresses the challenge of managing the waste generated by these vehicles, which is a critical aspect of reducing the environmental impact of cities.

-

SDG 12: Responsible Consumption and Production

This is the most central SDG to the article. The entire project is a response to the “wave of expired lithium-ion batteries with no affordable way to recycle them.” The initiative promotes the environmentally sound management of waste and aims to “substantially reduce waste generation through… recycling,” creating a circular economy model where waste from one industry becomes a valuable input for another.

-

-

Specific Targets Identified

Based on the article’s content, several specific SDG targets can be identified as directly relevant to the project’s objectives and methods.

-

Target 2.4: Sustainable food production systems

By 2030, ensure sustainable food production systems and implement resilient agricultural practices that increase productivity and production. The article supports this target by developing a new source of fertilizer, which is described as “essential for increasing crop yields.” The project aims to “support agriculture in Wisconsin and beyond.”

-

Target 9.4: Upgrade infrastructure and retrofit industries for sustainability

By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies. The described process is an “environmentally sound” technology that increases resource efficiency by recovering valuable elements from waste batteries to produce fertilizer with “less energy” than mining or transporting raw materials.

-

Target 9.5: Enhance scientific research and upgrade technology

Enhance scientific research, upgrade the technological capabilities of industrial sectors… encouraging innovation. The article is centered on a scientific “proof of concept” developed at a university, funded by a “Discovery and Innovation Grant,” which exemplifies the enhancement of research and innovation to solve industrial problems.

-

Target 11.6: Reduce the environmental impact of cities

By 2030, reduce the adverse per capita environmental impact of cities, including by paying special attention to… waste management. The project directly addresses the management of a specific and growing type of urban waste—expired batteries from electric vehicles—thus helping to mitigate the environmental impact of cities.

-

Target 12.5: Substantially reduce waste generation

By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse. The project’s primary goal is to recycle the “wave of expired lithium-ion batteries,” directly aligning with this target by turning a waste product into a high-value commodity and preventing it from becoming a disposal problem.

-

-

Indicators Mentioned or Implied

The article implies several indicators that could be used to measure progress towards the identified targets, even if specific quantitative data is not provided.

-

Indicator for Target 2.4: Crop Yield

The article explicitly mentions a plan to “conduct comparative field tests against conventional fertilizers” through a “one-acre tomato crop trial.” The results of this trial would serve as a direct indicator of the fertilizer’s effectiveness in increasing agricultural productivity.

-

Indicator for Target 9.4 & 12.5: Volume of Waste Recycled and Resource Efficiency

An implied indicator is the amount of battery waste diverted from traditional disposal. The success of the project can be measured by the quantity of LFP batteries processed. Furthermore, the reduction in energy consumption compared to traditional mining and transport of fertilizer ingredients is another key performance indicator of resource efficiency.

-

Indicator for Target 8.2 & 9.5: Economic Value and Job Creation

The project aims to create an “economic opportunity.” An indicator of success would be the market value of the fertilizer produced from the recycled batteries. The article also states the project will “create high-tech jobs,” so the number of jobs created in this new green technology sector would be a direct indicator of progress.

-

Indicator for Target 12.2: Domestic Production Volume

The article highlights the goal of creating a “ready domestic supply” of fertilizer ingredients to “reduce reliance on foreign imports.” A key indicator would be the volume of fertilizer produced domestically through this method, which would directly measure the project’s contribution to resource independence and sustainable management of natural resources.

-

-

Summary Table of SDGs, Targets, and Indicators

SDGs Targets Indicators SDG 2: Zero Hunger Target 2.4: Ensure sustainable food production systems and implement resilient agricultural practices that increase productivity. Comparative crop yield from field tests (e.g., the “one-acre tomato crop trial”). SDG 8: Decent Work and Economic Growth Target 8.2: Achieve higher levels of economic productivity through diversification, technological upgrading and innovation. Number of “high-tech jobs” created; Economic value of the fertilizer produced from recycled materials. SDG 9: Industry, Innovation, and Infrastructure Target 9.4: Upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency. Volume of domestically produced fertilizer from recycled batteries, reducing reliance on imports; Reduction in energy used compared to mining raw materials. SDG 11: Sustainable Cities and Communities Target 11.6: Reduce the adverse per capita environmental impact of cities, including by paying special attention to waste management. Tonnage of EV battery waste managed and diverted from landfills annually. SDG 12: Responsible Consumption and Production Target 12.5: Substantially reduce waste generation through prevention, reduction, recycling and reuse. Recycling rate of lithium iron phosphate (LFP) batteries; Percentage of battery materials recovered and repurposed into fertilizer.

Source: wisconsin.edu